OVERVIEW

Many of our daily actions and tools require electricity, but oftentimes we do not realize that men and women are risking their lives to keep the power running. Behind the scenes, operators work on large, metal devices called switchgears that distribute electrical current to buildings. These switchgears handle fatal levels of electricity, which means that working with switchgears is a high-risk, high-stress job where one careless act could mean injury or death.

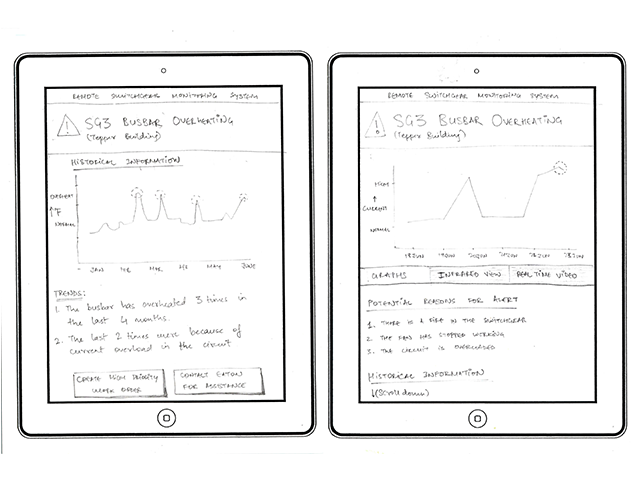

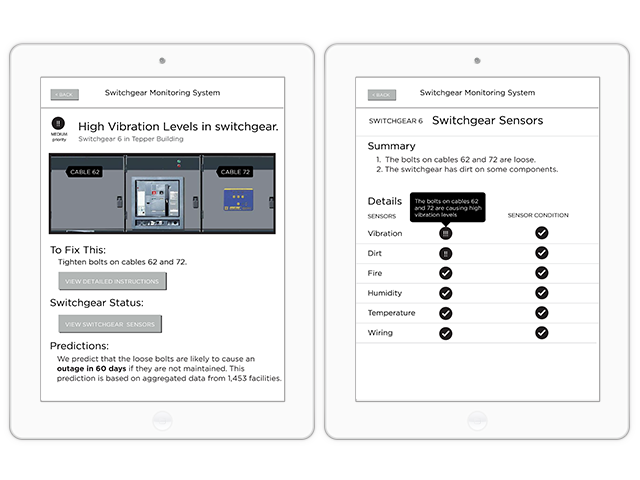

The scope of our project is to design the future of the switchgear-human interaction in the North American commercial sector, specifically in universities and hospitals. This project spans an 8-month period, starting with the research and synthesis phase from January to May 2014, and ending with the prototyping and testing phase from May 2014 to August 2014.